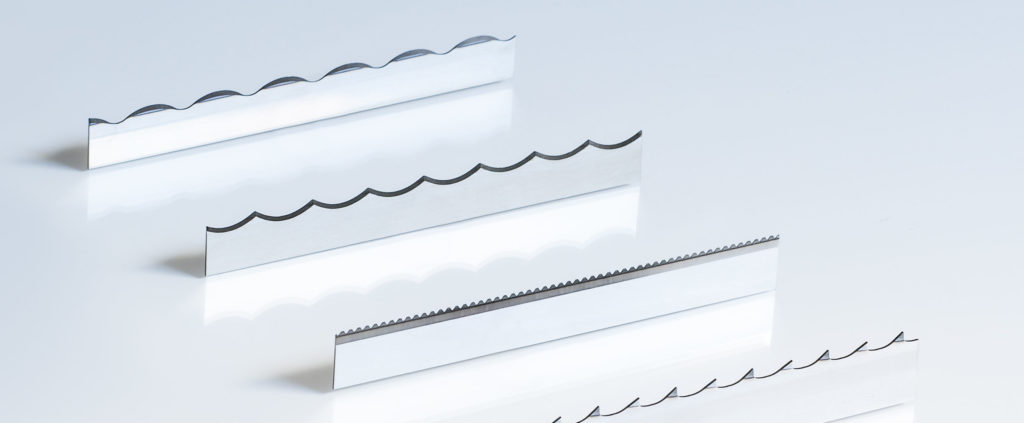

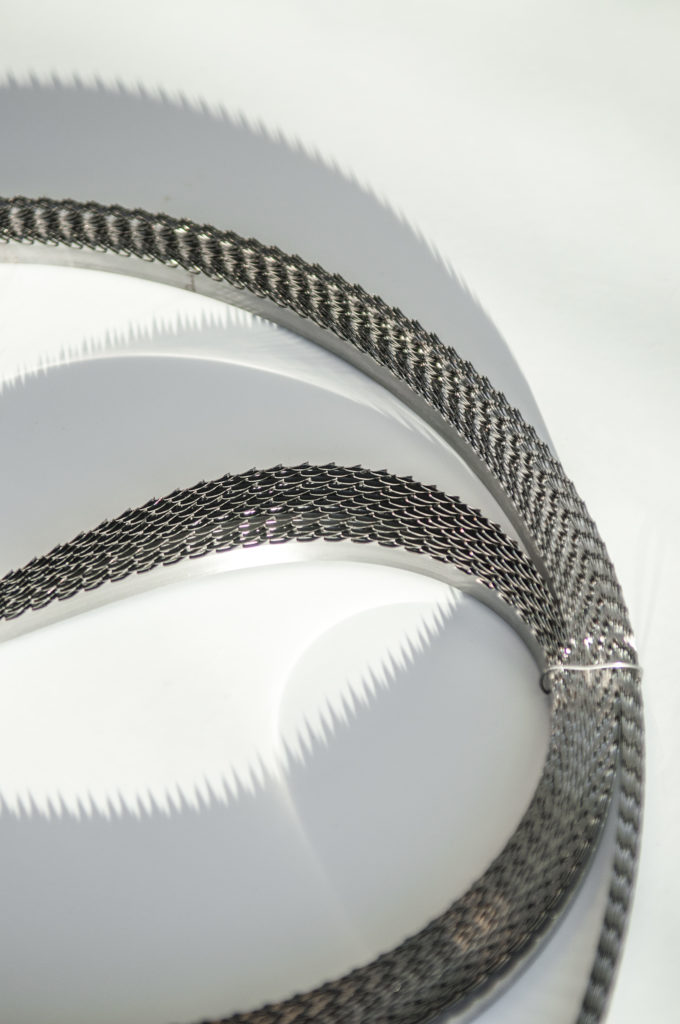

From punching every single blade in the late 1940’s, our production process has been developed into a top modern production line. Automation and Lean have been key focus in order to provide our personnel with a good working environment and ultimately top of the line products.